The calves are doing great – we have 1 bull and 2 heifers so far this fall. Here are a couple of pictures from late August. The red calf is a heifer.

The calves are doing great – we have 1 bull and 2 heifers so far this fall. Here are a couple of pictures from late August. The red calf is a heifer.

I bought a couple of large square bales of hay last time I was at the local feed store to try them out. They can be a disaster! If you have a tractor that can lift them and enough cattle to put them in the field with little waste before they get too wasted, they would be great. The big advantages, IMO, are that they stack really well, and are very large. The biggest disadvantage is that if you store them in the barn and feed portions at a time, they completely fall apart when you cut the strings.

I ended up building a carrier for the tractor out of a pallet and some scrap lumber that will allow me to carry a couple of flakes out to the cows using the pallet forks. It works really well so far. I also used a bungee strap and a couple of hay hooks over the top of the bale to hold the bale together and allow me to release a couple of flakes at a time instead of the entire bale falling apart.

Here is the contraption on the pallet forks, with a couple of hungry dexters eating from it. Cascades Contender looks like he wants to climb in and go for a ride.

Update: I recently bought a bunch of large square bales and have been using my round bale cradle feeder to feed them. I attached a section of hog panel to the base of the cradle feeder to reduce waste, and I am getting 4 days per bale, if I move the herd each day. I have 12 head of cattle right now.

The square bale does not fit initially, but I when I cut the strings and pull a little bit off each end, it falls into the feeder.

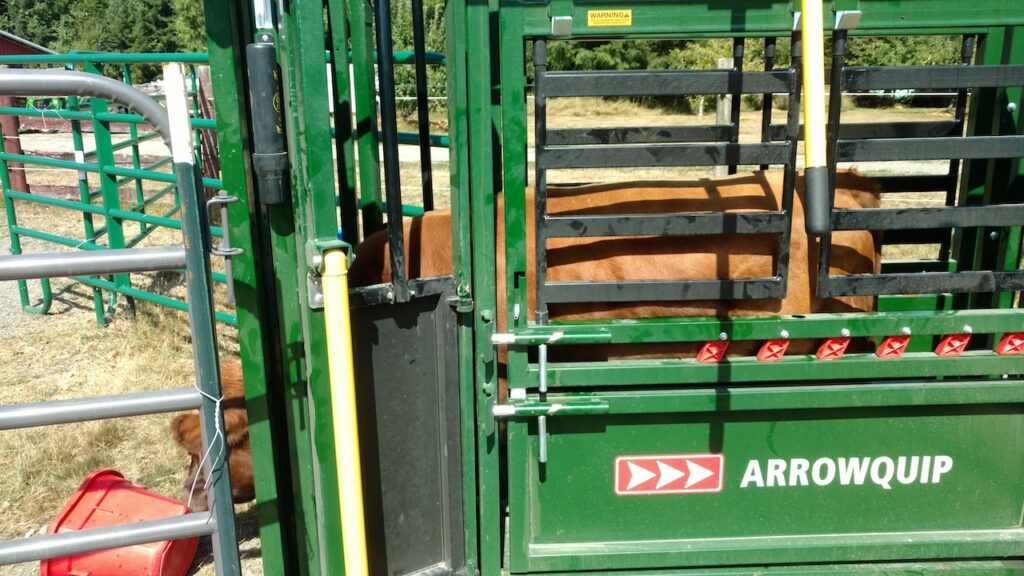

On Thursday I went to Pearson Farm & Fence in Moses Lake, WA to pick up our new Arrowquip Q-Catch 74 Series Squeeze chute. This is a new design that is much less expensive than the 86 series. I believe it’s a bit smaller and they have been running a special at $4250, so I felt the price was right and I needed one, so I bought one.

I can’t say enough good things about Pearson Farm & Fence. They helped me out every step of the way and were very good to work with. Check them out if you’re ever in Moses Lake, WA.

Arrowquip has been great to work with as well. The chute looks and operates very nicely. I have never had or used one before, but this one has so many cool features, I am glad I bought it.

I set it up right by the pen where we keep our yearling bull, soon to be steer. We have some tarps setup around his pen to keep him from seeing the other bull in the pasture. I think this greatly reduces the bellowing, especially at night. Having more than one bull can be an adventure, and I don’t recommend it.

Here is Beauford, the circus bull, on his way to becoming the circus steer:

I setup the chute and put a bucket with a little scoop of grain inside, as well as some apple slices. I came back a few hours later and he had eat them, so I put a few more apple slices in and he walked right in. I clamped him down and gave him a tetanus shot. Much easier than I expected. Next step, call the vet and schedule the second step.

We bought a new bull on Saturday – Cascades Contender. What a great bull! We drove down to Sandy, Oregon and picked him up from Cascade Meadows. Kirk and Jason are great and do wonderful things for the Dexter world! They had him haltered and waiting when we drove up and they led him into the trailer. I would never have believed it if I hadn’t seen it.

What a good looking bull. He’s very compact and will allow us to breed more compact cows and beef. He’s 39″ at the hips.

While it’s not the best timing – we are expecting 5 calves by October. We have had two born already, on 8/5/20 and 8/13/20. Both are black calves, one bull and one heifer. Both polled and from our exceptional bull, Cascades Forrest.

We butchered our 39 Cornish Cross meat birds the weekend of August 8th. I don’t remember if it was Saturday or Sunday. It was great. It took us all day, since it was the first mass butcher we’ve done and we had to get all the kinks worked out of the process.

The killing cones are terrible — we won’t use those again, and I am selling 4 big ones ASAP. It’s much easier to chop the heads off or use a gallows system like what we started to use.

Next time we need a better system to transport the chickens to the butcher location. We started the tractor right about where we needed it to end, so transporting the chickens in a large dog crate took a lot of time and energy. Perhaps we’ll use a trailer next time like Pete from Just a Few Acres Farms (find him on Youtube).

The chicken tractor didn’t go as far as we thought it would! This is not a bad thing. 5 weeks of moving the cornish cross chickens at least once each day, and sometimes twice, resulted in a long stretch of ground covered, but we thought it would be twice as long. I guess math works, so we could have used that.

Overall, it was a good experience. We have a lot of meat in the freezer and chicken feed left over. We will do this again next year and do more so we can sell more. Contact us using the contact form from the top menu to get on the list for next year.

We put our first batch of meat birds out on pasture in our new tractor today. These birds are 3 weeks old.

First, a couple of pictures of the birds in the brooder. Here are two custom brooder boxes, each is 3’x4′. The boxes have guillotine doors that are both open to allow them access to both boxes at the same time.

Here are a few pictures of the birds in the tractor on grass.

We just finished building a “Joel Salatin” style chicken tractor to tractor our meat birds around the pasture. We’ve built and tried a lot of different chicken tractors, but this one is sanctioned by the master of pastured poultry profits, so it should be great!

I tried to match the original design fairly exactly. I did use 2×4 lumber for the base with some re-enforcements to ensure it will be solid.

We’ll start using this on Wednesday with a batch of meat birds.

Scheduling a beef for butcher is a tough one. We’re working through the process for the second time now, for our own beef. The scheduling part is something you have to know months in advance. If you had an emergency and needed to get an animal in “right away”, I don’t know if that’s possible. We’re scheduled about 6 months out.

As far as running the business side of things, it will set a requirement to get a good deposit and commitment from customers for a share of the beef. The customer must then budget for the balance of the payment when the beef is ready for pick-up.

In an ideal world, a beef would be slaughtered at the end of the grass growing season. The taste and texture is best when the animal is in the growing phase of the season vs when nutrients are getting less nutritious or less available, in general. The age of the animal is less a factor than what (and how much) it’s eating at the time. All fall slaughter dates are very difficult to get unless scheduled 1 year in advance. The best time to slaughter is September/October as grass growth drops off precipitously in most places.

We initially had some concerns with putting a new calf in with the bull, but those concerns were completely unfounded. This bull is great with everybody. Here is our 10 year old herd bull Forrest with our 6 week old heifer calf.